Contents hide

2 Advantages Over Traditional LED Screens

3 Merits of the COB LED Screen

4 The Shadows of COB LED Displays: Unveiling Drawbacks

5 Choosing OneDisplay's COB LED Screen: A Wise Endeavor

What is COB LED Screen?

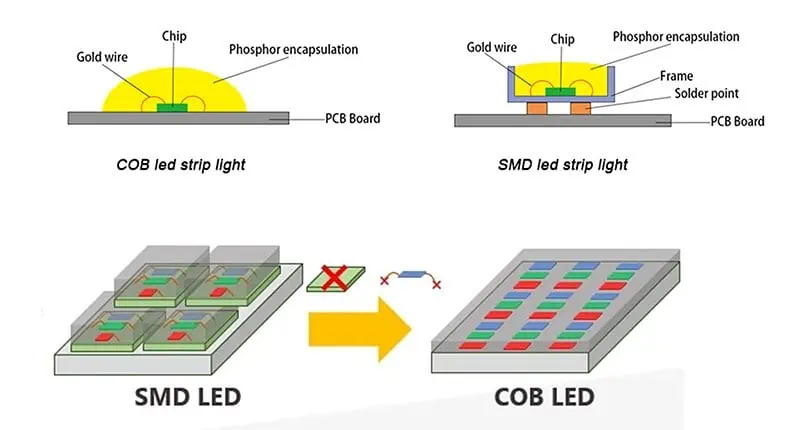

COB (Chip on Board) is also a kind of LED display packaging technology. Unlike traditional LED screens, COB technology involves mounting multiple LED chips directly onto a circuit board, eliminating the need for individual packaging. This consolidation enhances brightness, reduces heat emission, and enables a more seamless display.

Advantages Over Traditional LED Screens

COB LED screens outshine their counterparts in terms of performance. The absence of gaps between LED chips ensures uniform lighting, preventing issues like the “screen door effect.” Additionally, COB screens offer better color accuracy and higher contrast ratios.

Advantages of COB LED Screen

Owing to the diminutive size of the LED chip, COB offers a significantly heightened packing density when juxtaposed with Surface Mount Device (SMD) technology. This manifests as a more compressed array, ensuring enhanced uniformity, heightened intensity even in proximity, and superior heat dissipation, bolstering stability, reliability, and longevity. The encapsulation of COB chip and pin legs augments airtightness, fortifying resistance against external forces, yielding a seamless, polished surface. Moreover, COB boasts heightened resistance to moisture, ElectroStatic Discharge (ESD), damages, and dust, flaunting an IP65 surface protection rating.

Stable technological process. As shown above, SMDs need to use reflow soldering. When the soldering paste reaches a temperature of 240°c the epoxy resin weight loss rate is 80% which easily causes the glue to separate from the LED cup, but in the case of COB technology there is no reflow soldering process so it is more stable.

A Closer Look: Pixel Pitch Precision Pixel pitch, denoting the proximity of pixels on a display, undergoes refinement with COB LED technology. The smaller pixel pitch translates to increased pixel density, yielding superior resolution. This reduction in pitch ensures clarity even for viewers in close proximity to the display.

Illuminating the Dark: Light Efficiency

Efficient heat dissipation and low light attenuation hallmark COB LED technology. Direct dispensing of the COB chip onto the PCB expands the heat dissipation area, surpassing the SMD counterpart in attenuation. SMD's heat dissipation emanates from the bottom of its anchoring.

Expanding Horizons: Viewing Angles

The small pitch technology within COB bestows a broader viewing angle, transcending indoor and outdoor scenarios with heightened brightness.

Indomitable Resilience

COB stands resilient against collisions, impervious to the impact of Oil, Damp, Water, Dust, Oxidation, and dust.

High Contrast Ratio

The contrast ratio, a pivotal metric for LED displays, achieves new heights with COB, boasting a static contrast ratio between 15,000 to 20,000 and a dynamic contrast ratio reaching 100,000.

The Green Epoch: Energy Efficiency

In the realm of energy efficiency, COB surges ahead of SMD, a critical factor in the operational cost of expansive displays subjected to prolonged usage.

The Shadows of COB LED Display: Unveiling Drawbacks

Crafting Challenges

The encapsulation of an LED display within COB mandates a defect-free lamp before refilling. Unlike SMD packaging, individual bulb replacement is unfeasible, intensifying the stringency of the packaging process.

Maintenance Dilemma

Traditional SMD packaging allows for unit board disassembly after a single LED soldering repair. In contrast, COB products complicate maintenance, impacting surrounding lamps. Despite enhanced protection, a discernible dead light rate persists, necessitating unit board replacements. Although COB panels incur higher costs, their failure probability is substantially lower, making the maintenance cost comparable to SMD. As COB manufacturing costs decline, the trajectory suggests COB LED screens may soon eclipse SMDs in cost-effectiveness.

Choosing OneDisplay's COB LED Screen: A Wise Endeavor

OneDisplay stands as a stalwart display provider, presenting the Mini COB LED Screen adorned with three distinct advantages:

Pioneering Technology: Leveraging COB full flip-chip packaging technology enhances the performance and yield of small-pitch LED displays.

Exemplary Performance: OneDisplay's Mini COB LED displays embody attributes such as absence of light stringing, sharp imagery, vibrant color reproduction, efficient heat dissipation, prolonged lifespan, high contrast ratio, expansive color gamut, elevated brightness, and swift refresh rates.

Economical Elegance: The Mini COB LED Screen from OneDisplay touts energy efficiency, easy installation, minimal maintenance requirements, low associated costs, and a commendable cost-benefit ratio.

Pixel Prowess: Covering a pixel pitch spectrum from P0.93 to P1.56mm, OneDisplay accommodates various user requirements.

- 1,200nits brightness

- 22Bit grayscale

- 100,000 contrast ratio

- 3,840Hz refresh rate

- Exceptional protection performance

- Single Module Calibration Technology

- Adherence to industry standards and specifications

- Proprietary optical display technology prioritizes eye protection

- Versatile applicability across various scenarios

Content hidden

1 What is COB LED screen?

2 Advantages over traditional LED screens

3 Advantages of COB LED screen

4 Shadows of COB LED Display: Revealing the Disadvantages

5 Choosing OneDisplay COB LED Screen: A Wise Try

What is COB LED screen?

COB (Chip on Board) is a kind of LED display packaging technology. Unlike traditional LED screens, COB technology mounts multiple LED chips directly onto a circuit board, eliminating the need for individual packaging. This integration increases brightness, reduces heat generation, and enables smoother display.

Advantages over traditional LED screens

COB LED screens outperform their peers in terms of performance. The lack of gaps between the LED chips ensures uniform lighting, preventing problems such as the “screen door effect.” In addition, COB screens offer better color accuracy and a higher contrast ratio.

corn on the cob

Advantages of COB LED screen

Due to the small size of the LED chip, COB offers significantly increased packaging density compared to Surface Mount Device (SMD) technology. This results in a more compact package, which provides increased uniformity, increased intensity even at close range, and excellent heat dissipation, reinforcing stability, reliability, and long life. The encapsulation of COB chips and pins increases air tightness, reinforcing resistance to external forces, resulting in a seamless, polished surface. In addition, COB is highly resistant to moisture, electrostatic discharge (ESD), damage, and dust, and has an IP65 surface protection rating.

Stable technological process. As shown above, SMDs need to use reflow soldering. When the solder paste temperature reaches 240°C, the weight loss of epoxy resin is 80%, which makes the adhesive easily peel off from the LED cup, but COB technology does not have a reflow soldering process, so it is more stable.

In detail: Pixel Pitch Precision The pixel pitch, which indicates the closeness of the pixels on the screen, is refined with COB LED technology. The smaller pixel pitch results in a higher pixel density, resulting in excellent resolution. This pitch reduction ensures clarity even for viewers close to the display.

Lighting up the darkness: Light efficiency

Efficient heat dissipation and low light attenuation are the hallmarks of COB LED technology. The direct application of the COB chip to the PCB increases the heat dissipation area, surpassing the SMD equivalent in attenuation. The heat dissipation of the SMD comes from the bottom of the fixture.

Expanding horizons: perspectives

COB's short-throw technology provides a wider viewing angle that surpasses indoor and outdoor scenarios with increased brightness.

cob1

Unstoppable flexibility

COB is impact resistant, resistant to oil, moisture, water, dust, oxidation and powder.

High contrast ratio

Contrast ratio, a key metric for LED displays, reaches new heights with COB, boasting a static contrast ratio of 15,000 to 20,000 and a dynamic contrast ratio of 100,000.

The Green Era: Energy Efficiency

COB outperforms SMD in terms of energy efficiency, which is a critical factor in the operating costs of large displays exposed to prolonged use.

Shadows of COB LED Display: Revealing Disadvantages

Crafting challenges

Encapsulating the LED display within the COB requires a defect-free lamp before repackaging. Unlike SMD packaging, individual bulb replacement is not feasible, which increases the rigor of the packaging process.

Maintenance dilemma

Traditional SMD packaging allows the unit board to be disassembled after soldering a single LED. In contrast, COB products make maintenance difficult and affect the surrounding lights. Despite the increased protection, the rate of dead light is still noticeable, which requires replacing the unit board. Although the cost of COB panels is higher, their probability of failure is significantly lower, so the maintenance cost is comparable to SMD. As COB manufacturing costs decrease, the trajectory suggests that COB LED screens may soon eclipse SMDs in terms of cost-effectiveness.

Choosing OneDisplay COB LED Screen: A Wise Try

OneDisplay is a reliable display provider that adorns the Mini COB LED screen with three distinct advantages:

Pioneering technology: Utilizing COB's full flip-chip packaging technology increases the performance and yield of small pitch LED displays.

Exemplary Performance: OneDisplay Mini COB LED displays embody features such as no light streaks, sharp images, vivid color reproduction, efficient heat dissipation, longer lifespan, high contrast ratio, extensive color gamut, increased brightness, and fast refresh rate.

Economical elegance: OneDisplay Mini COB LED display represents energy efficiency, easy installation, minimal maintenance, low associated costs and a commendable cost-benefit ratio.